Milliken solutions for polypropylene (PP)

Enhance production speed and productivity

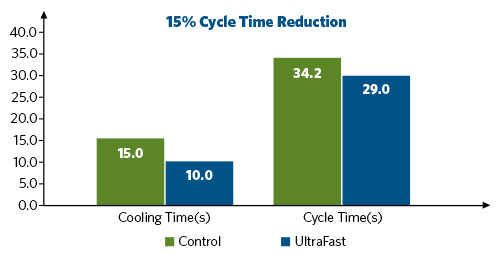

We offer solutions that raise the crystallization temperature and the rate of crystallization. These solutions can help to reduce cycle times, helping to boost the productivity of your processes.

Improve stiffness/impact balance

Adding nucleators to polypropylene often increases stiffness at the expense of impact strength. Our solutions overcome this challenge to improve stiffness while retaining the same impact behavior. The resulting products are stronger, thinner and stable at high temperatures.

Reduce isotropic shrinkage

Polypropylene is a semi-crystalline polymer which shrinks after molding. The nucleator influences the absolute shrinkage and the ratio of machine/mold direction shrinkage to transverse direction shrinkage (MD/TD shrinkage). Our solutions impart excellent isotropy, resulting in reduced warpage and stable dimensions in the end-product. As well as enhancing quality, they help to reduce waste and make production more efficient.

Achieve stable dimensions in any color

Pigments nucleate polypropylene to different degrees, which makes it difficult to mold parts with identical dimensions. Some pigments also have anisotropic shrinkage properties that can cause part warpage. Milliken solutions allow converters to override the nucleation effect of pigments so that they can produce a variety of colored parts with identical dimensions using the same mold and production conditions. This reduces design complexity and increases the quality and consistency of the final product offer.

Improve the transparency of PP

Our solutions give PP parts a transparency boost that overcomes the milky appearance of PP in injection molded, blow molded, and thermoformed applications. The result is high level of clarity that makes PP a viable alternative to traditional clear materials such as PET, PS and glass.

Find out more about NX® UltraClear™ PP

Add bright, clear colors to clarified PP

We offer colorants that allow converters and brand owners to create attractive colored PP parts. These additives offer vivid, transparent color to enhance aesthetics while maintaining the crystal-clear appearance of Millad® NX® 8000 clarified polypropylene.