Nucleation: how Hyperform® HPN works

Normal PP

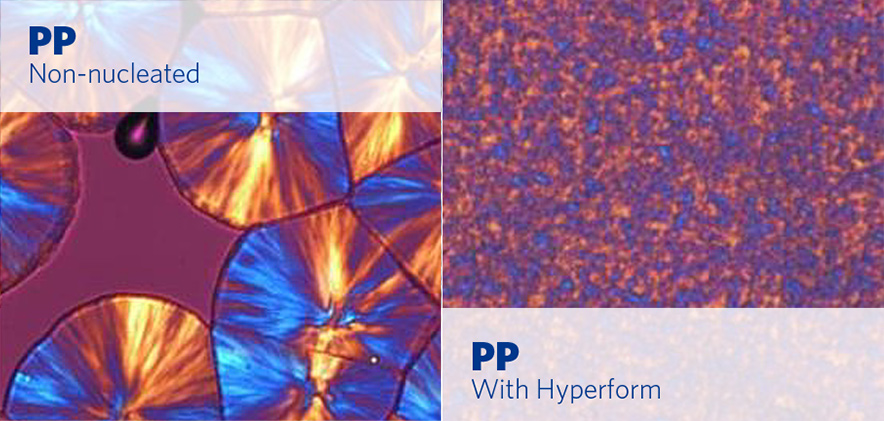

As the polymer crystallizes from the melt, complex macro-structures known as spherulites form. These are responsible for scattering light and their size and orientation can dictate the polymer’s optical and physical characteristics.

Nucleated PP

To improve clarity and/or physical properties, the size and orientation of the polymer crystals must be controlled. By providing multiple sites for nucleation, nucleating agents affect the kinetics of polymer crystallization and increase the temperature of crystallization, ‘freezing’ the polymer at a higher temperature. These changes can accelerate process cycle time but, if they are imbalanced, they can lead to residual stresses which warp the shape of the final part. Through its high nucleation density and extremely rapid nucleation kinetics, Hyperform HPN enables better control of this process compared to conventional nucleators. Similarly, nucleators can help to orient polymer crystals resulting in increased stiffness. HPN provides the ability to balance improved stiffness with optimal impact performance and low, isotropic shrinkage.

Why choose Hyperform HPN?

Traditional nucleating agents can require high loading levels, which increase costs and make handling more complicated at your plant. They may also be hard to disperse, polymer shrinkage is often anisotropic and quality can vary between batches. With Hyperform HPN performance additives, shrinkage is isotropic, and levels of shrinkage are low. The stiffness/impact balance is frequently improved, as are product aesthetics. Hyperform HPN performance additives have the potential to speed up your processes and are effective at low loading levels, improving the cost-efficiency of the overall formulation. They do not present any of the health and safety issues linked to some conventional nucleating agents.