How are Reactint colorants used?

Reactint Colorants are homogeneous liquids which are fully miscible in polyol, do not require stirring prior to use and are easy to clean up. Their low viscosity and high surface tension make Reactint colorants easy to use in color systems at room temperature. Unlike pigments, they are non-abrasive and will not damage pumps, nozzles, tank linings and other equipment components. These versatile colorants can be used in both polyether and polyester urethane systems.

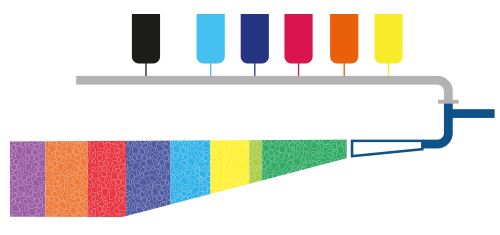

1. Reactint Blend-on-the-fly System

With only a few tanks of Reactint primary colors, a wide range of colors can be produced automatically while pouring slabstock foam.

2. Reactint In-line Dosing System

A unique in-line blending method injects the liquid colorant straight into the polyol stream, at the desired dosage, for a simpler, cleaner process.

Expert support for your business

We offer global technical support with a wide range of analytical capabilities to meet your needs. Our services include fast, efficient color matching and broad expertise in implementing color dosing systems.

How do Reactint colorants differ from pigments? See the technology.