How do ClearShield™ UV absorbers work?

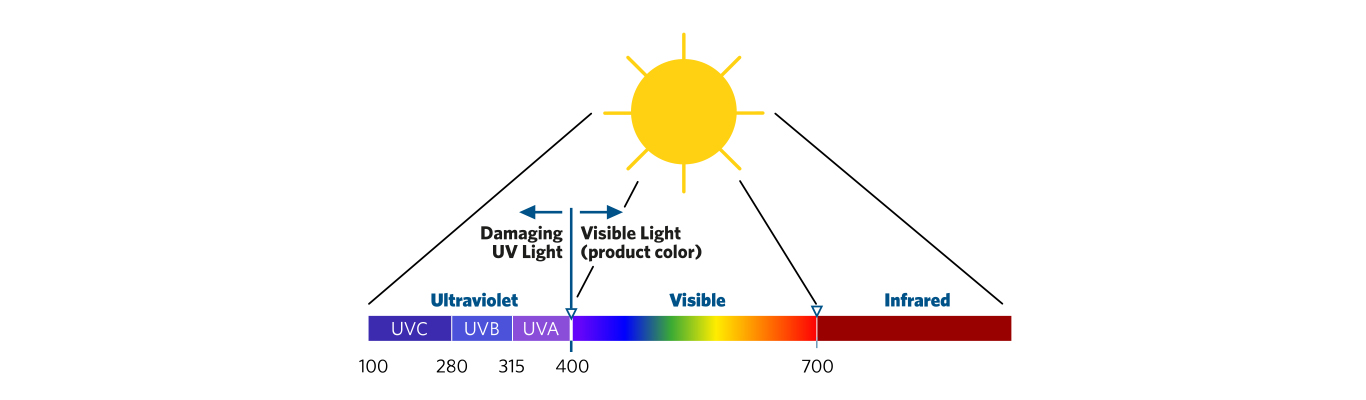

ClearShield is a strong UV-absorbing chromophore for polyethylene terephthalate (PET). To offer the best protection against product degradation, UV absorbers should only block damaging UV light, without affecting the visible light that is essential to the product’s color.

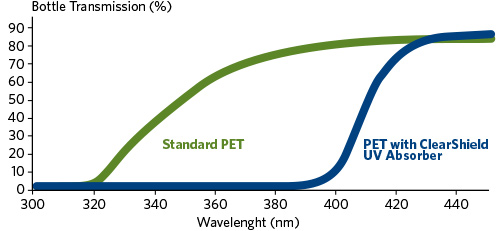

Whereas untreated PET allows the passage of significant UV radiation above 320 nanometers (nm), ClearShield filters almost all UV radiation – 95% of UV at 390 nm. It does this while preserving the aesthetics of the product.

ClearShield™ in your processes

The additive is supplied as a homogenous liquid for easy handling and metering and is used by converters in a wide array of commercially available resins. Unlike other UV absorbers, ClearShield bonds permanently to the PET, becoming an integral part of the matrix. As a result, it does not extract into beverages or other packaging contents and it is approved for food contact applications. ClearShield does not plate-out onto injection molded equipment or bottle preforms. It is effective at low loadings, making it a cost-effective alternative to traditional technologies.