Using the ancient art of screen printing to make next-generation electrochromic biosensors

September 18, 2019 by Philippe ScheerlinckElectrochromic technology has advanced tremendously in the past few years, particularly in the field of sensors that exploit color changes to trigger a response; think of smart glass or display screens. Yet, conventional electrochromic sensors rely heavily on silicon-based electronics, that are complex and costly, preventing a broader uptake of these smart systems.

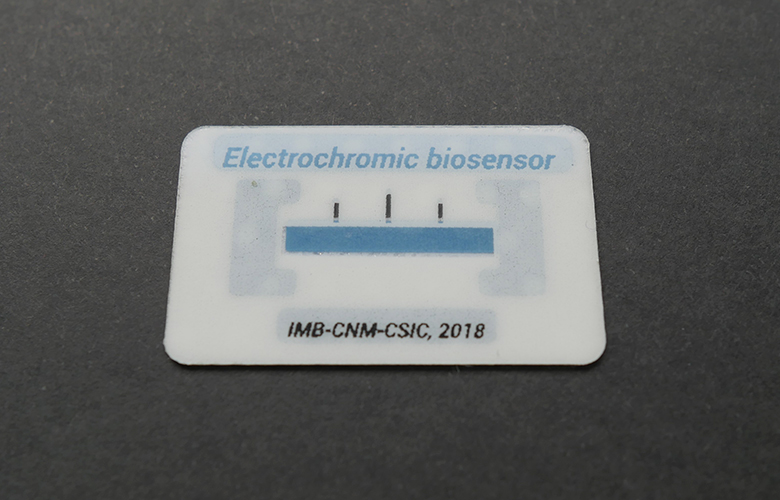

Now, in breakthrough research in Spain, scientists have developed a next-generation, self-powered Prussian-Blue-based electrochromic screen-printed biosensor1, overcoming the need for silicon-based electronics entirely2. It’s the first time that screen printed electrochromic technology has been combined with a biosensor, with potential exciting applications in medical diagnostics and beyond.

Three functions in a single electrochemical cell

With a background in electrochemistry, Dr Javier del Campo, at the Instituto de Microelectrónica de Barcelona, was interested in the unconventional applications of electrochromic materials, beyond displays and smart glass. More than glass just changing color, del Campo wondered, would it be possible to measure the concentration of a substance by looking at a color change?

The research stemmed from a previous project where del Campo, and his colleagues, developed a disposable blood glucose and lactate analyser. Many of the components were screen-printed, but they still needed to use several discrete components that had to be attached to the main (printed) board.

“Our vision was to simplify the device to the point where there was only one component. If we could build a self-powered sensor using an electrochromic electrode, in principle we could have three functions in a single electrochemical cell: sensor, display, and power source”, del Campo said. So he, and his colleagues, set about developing a screen-printed electrochromic quantitative biosensor that could operate in the absence of silicon-based electronics.

Unique properties of Zelec Electroconductive Powders

They produced working prototypes by screen-printing and chose Prussian Blue as the key electrochrome, due to its easy preparation in a lab and relative biocompatibility. To exploit its electrochromism Milliken provided the researchers with its Zelec powders to provide good electrical contact between the electrode and the electrochrome. In addition to its conductivity, another advantage was Zelec’s relatively clear, not black, coloring, allowing a user to see color changes well3.

“Milliken is proud to be associated with this cutting edge project through its Zelec Electroconductive Powders and their unique properties and we look forward to the exciting applications that may continue to come out of this research,” said Dr Philippe Scheerlinck, Milliken’s Senior New Business Development Manager EMEA.

“This new electrochromic technology was then used with known and tested enzyme-based biosensors adapted to this approach for a proof of concept,” said del Campo, continuing, “it represents a breakthrough for self-powered sensors extending the application of electrochromic materials beyond smart windows and displays, into sensing and quantification.”

Whilst this work is still in its infancy commercial applications for the current generation of electrochromic sensors are growing. The technology has been successfully used to develop smart windows for architectural buildings, in the auto-dimming of rear view car mirrors, for thermal control in satellites and for camouflage. A prominent example of the successful commercialization of electrochromic sensors can be found in the Boeing 787 Dreamliner, where its windows use the technology to dim, replacing traditional airline window shades4,5.

And biosensors are nowadays ubiquitous in biomedical diagnosis, as well as a wide range of other areas, such as point-of-care monitoring of treatment and disease progression, environmental monitoring, food safety, drug discovery, forensics and biomedical research6.

Combining electrochromic and biosensor technology opens up the possibility of a myriad of new applications, ranging from robotic skin, biometric devices, the human‐machine interface, and energy devices, to soft electronics and optoelectronic devices.

Enhanced quality and durability

Whilst this research has now come to an end, del Campo and his colleagues are developing many of the ideas that came out of the project to make more stable and better sensors. “It is hard to say where this technology will be in 5 to 10 years as there are so many questions to answer and routes to explore. So far, we have identified two different evolutions for these analytical devices using electrochromism, but we are only considering device configurations. The possibilities, really, are endless, as other phenomena such as electrochemiluminescence or electrofluorescence can also be exploited in analytical applications,” he concludes.

Zelec electroconductive powders (ECPs) provide cost-effective, static-dissipative performance for coatings and polymers. They are non-volatile, non-corrosive, and resistant to heat, chemicals and humidity. They also enhance quality and durability by imparting resistivity throughout the lifetime of coatings, paints, security inks and electronics products.

Used instead of conductive agents such as carbon black and metals, Zelec ECPs are compatible with a broad spectrum of colors. They can be used in injection molding and extrusion, in thermoset systems and in solvent or water-borne coatings and inks. The product family includes several unique powders that perform over a wide range of surface resistivity while allowing you to optimize loading for greater efficiency.

The research was funded by FEDER funds, managed by the Catalan Secretary of Universities and Research, through project SEAMLESS (PROD-0000114; Enterprise and Knowledge, Industry Department, Generalitat de Catalunya). Javier del Campo also gratefully acknowledges financial support through a 2016 Leonardo grant from the BBVA Foundation.

References:

1https://www.sciencedirect.com/science/article/pii/S0925400519304575

2https://pubs.rsc.org/en/content/articlelanding/2017/sc/c6sc04469g#!divAbstract

3https://www.sciencedirect.com/science/article/pii/S1388248118301541

4https://www.sciencedirect.com/topics/materials-science/electrochromics

5https://onlinelibrary.wiley.com/doi/book/10.1002/9783527679850

6https://www.journals.elsevier.com/biosensors-and-bioelectronics