Six key polyurethane mattress trends for the next decade

July 08, 2020 by Jesse Shoultz and Antoni PuigForm and function is the perfect balance between construction and aesthetics, and over the decades it has become one of the world’s most recognizable styles. Now, this design approach is making its mark in the development of a product important to us all, the humble mattress, driven by six global trends that show no signs of slowing.

It’s a globalized world

The polyurethane industry (PU) has evolved significantly in the last decade, through continuous innovation and the demand for more sustainable and higher quality materials.

In order to produce a single mattress, raw materials produced in every corner of the world are used, starting with polyols and isocyanates, and continuing with any small additive used to enhance the foaming reaction and to provide the final quality and aesthetics that the foam requires.

PU mattress production is currently worth almost 30-billion dollars annually with the Asia-Pacific region a powerhouse in production, accounting for almost 50% of all mattresses made1.

Lay-down comfort

We all want a mattress that is comfortable and ensures a good night’s sleep. Continuous industry innovation, mostly driven by polyol developments and foam quality improvements, has allowed polyurethane to stand out as the material capable of meeting the most critical consumers’ requirements.

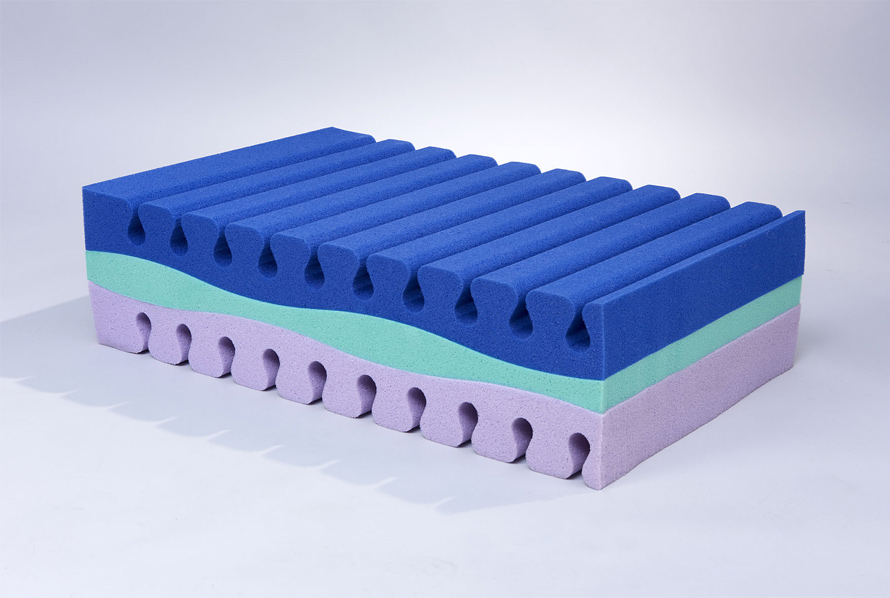

Simply, polyurethane foam has become the material of choice for millions of consumers thanks to its technical advantages. These advances have led to the development of multi-layered viscoelastic, hypersoft and high resilience foams with advanced quality, durability, breathability, comfort, superior thermal regulation, and body support for the mattress construction. Its increasing success is based on the improved foam quality and durability that make mattresses resistant, comfortable and breathable.

A sustainable night’s sleep

As companies across the value chain work towards creating a plastics circular economy, there have been significant advances in the sustainability of polyurethane foam in recent years.

There has been innovation in the development of polyether polyols, made with carbon dioxide, replacing some of the crude oil-based polyols traditionally used to make PU foam. This helps to close the carbon loop by bringing carbon dioxide, a waste greenhouse gas, back into the value chain.

However, end-of-life and the recycling of mattresses are the biggest challenges facing the PU industry, as every year millions of mattresses are either landfilled or incinerated. The PU industry has invested in technologies that are capable of breaking down the polyurethane bonds and recovering the polyol, making it valuable for re-use in new foam production.

In addition, certification schemes such as Certipur or Europe’s REACH legislation are helping to ensure the use of safer and healthier materials with reduced emissions.

Modern Manufacturing and e-commerce

Processes and manufacturing improvements in the last decade have driven cost reductions and increased foam quality. These changes include a further shift to automation, plant and process digitalization, and the reduction of scrap.

The growth of e-commerce has also revolutionized the polyurethane sector with, for example, new mattress concepts such as “Bed in a Box”. These mattresses, delivered to a customer’s doorstep, are the fastest growing trend in the mattress industry and require the use of high-quality foams with excellent recovery properties.

Sleep in a splash of color

It’s well known that consumers choose with their eyes and color is an important sensory part of this decision-making process. Until now mattress brands have not fully utilized color to differentiate their products but that is changing and Milliken’s Reactint® colorants for polyurethane are leading this trend.

To help manufacturers utilize the value of color Milliken has unveiled its Emerging Confidence ColorDirection 2022 trend report for PU mattresses with prominent trend colors that include: Welcoming Sunshine, a fresh, bright yellow that brings the positive warmth of mornings and the energy of light to your brand; Radiating Richness, a balanced purple created for positive products evoking luxury and self-care; and, Freshening Shoots a bright and vibrant green that represents ecology and sustainability, bringing new life to living.

Reactint at your fingertips

To help you create the perfect color combination Milliken has also launched its new, digital Reactint Color Studio – enabling customers to find a Reactint formulation for any Pantone number, with the color wheel, or for any shade in a photo. This allows you to build your own color mattress.

One of the benefits of Reactint colorants is the primary colorants principle in which, from five primary colorants, you can produce polyurethane in any shade by simple blending in-line before the mixing head. Over the years, Milliken’s global labs have color matched thousands of shades with these 5 primary colorants.

A new feature of the app is the ability to build your own mattress with different layers, creating adjustable thickness and different shades for each.

The way ahead

The mattress industry is evolving, driven by trends in globalization, comfort, sustainability, manufacturing, supply chain & e-commerce, and color. On its own, color has limited value, but in an industry that is continuously evolving and innovating, the use of color is a perfect way to highlight the value of each layer in a mattress. Color can ensure that everyone across the value chain, from the foam producer to the brand owner and the final consumer, fully understands the value and quality behind each foam layer.

Don’t get left behind and let Milliken help you to use the Power of Color to innovate and help your brand stand out from the rest.

Reference

1 The World Mattress Industry CSIL 2020