PET versus PP: Which plastic comes out on top in the sustainability stakes?

August 18, 2020 by Paul Kearns and Scott R. Trenor, Ph.D.A recent Life Cycle Assessment (LCA) of PET and PP trays has revealed some interesting insights into plastic packaging sustainability. Commissioned by Milliken, and conducted by the leading sustainability consultancy, Sphera, formerly known as thinkstep®, the purpose of the LCA was to better understand the relative environmental performance of polypropylene (PP) and polyethylene terephthalate (PET) when used to make thermoformed trays. Additionally, it aimed to highlight the hotspots in the product life cycle of both the PP and PET trays.

A hotspot is defined as contributing more than 25% of the product’s total impact as measured by the LCA. The main hotspots in the life cycle of these products are associated with raw material production. The extrusion process is also significant, as is end of life waste treatment when using energy recovery for all products, due to global warming potential.

“We wanted to understand how PP packaging performed when compared to its most logical alternative, PET. NX® UltraClear™ PP, clarified with Millad® NX 8000, has set a benchmark for crystal-clear polypropylene, giving it a glass-like transparency with a light weight, offering brand owners a cost effective alternative to traditional clear materials such as PET and glass. This makes understanding the environmental performance very important to us,” said Milliken’s Principal Scientist, Scott R. Trenor, Ph.D.

Putting the trays to the test

Both PP and PET trays are designed to package food, such as salads, and are considered to have equivalent functionality in terms of meeting packaging performance for this use. The functional unit for this LCA were equivalent volume trays with an identical mass of 9.1g.

LCA practitioners often argue about how to properly credit the use of recycled content in a product and there are two distinctly different approaches: end of life recycling (aka avoided burden) and recycled content (aka cut-off approach).1

In simple terms, avoided burden offsets the share of material that might be recycled at end of life, that is, a product is given ‘credit’ for recycling, but recycled materials are weighted as virgin.

In contrast, the cut off approach considers the share of virgin material offset by recycled material in the manufacture of a product. The recycled content portion is cut-off from upstream material burdens and bears only the environmental impact of the collection and processing of the recyclables.

In this LCA, Sphera deemed that the avoided burden approach was most appropriate because, for both PP and PET trays, it is reasonable to assume that whatever scrap is available and collected for recycling will actually be recycled, avoiding the requirement for virgin material in the next life.

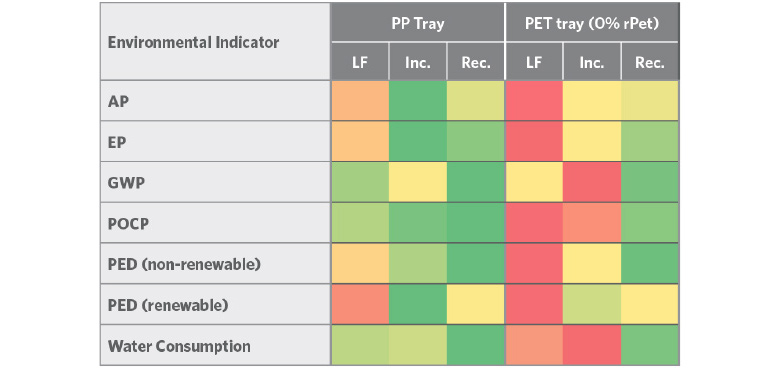

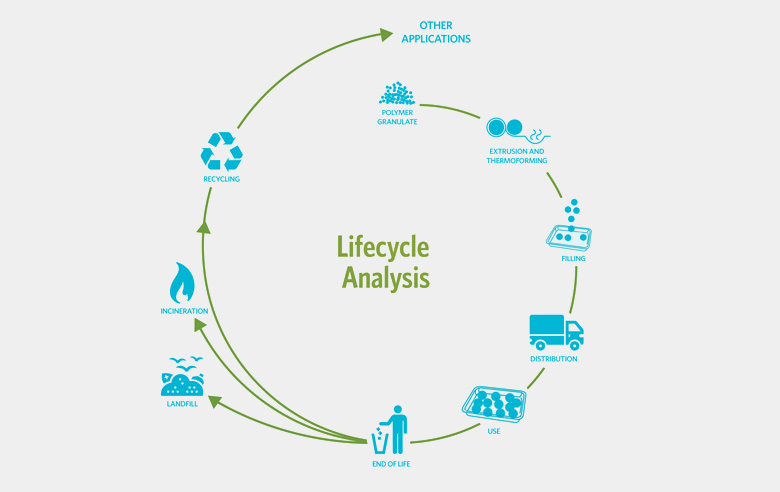

The LCA examined all aspects of the tray’s lifecycle from cradle to grave, starting with the production of polymer granulate and continuing all the way to the end of the package’s life – landfill (LF), recycle (Rec.) or energy recovery (Inc.). It also compared a series of common environmental indicators for each package. These were acidification potential (AP), eutrophication potential (EP), global warming potential (GWP), photochemical ozone creation potential (POCP), primary energy demand (PED) and water consumption.

This ‘heat map’ shows the relative impact intensity for both the PP and PET product in each of the environmental indicator categories. Both the PP and PET trays were made with virgin material only.

It clearly shows that when landfilled or incinerated PP has a significantly lower impact than the identical sized virgin PET. When recycled, the impacts are roughly equivalent due to the avoided burden allocation methodology.

Does using recycled content make a difference?

The short answer is that it depends on the methodology used in the LCA. This LCA also examined the effect of using recycled content in PET trays to determine if this led to a reduction in the environmental impact for this material. It assessed PET trays with different quantities of rPET against the PP trays made with virgin material only. That’s because regulations regarding the use of recycled content in plastic food packaging vary by region and, currently in the EU, recycled content in PET is allowed while in polyolefins (PP and polyethylene) it is not.

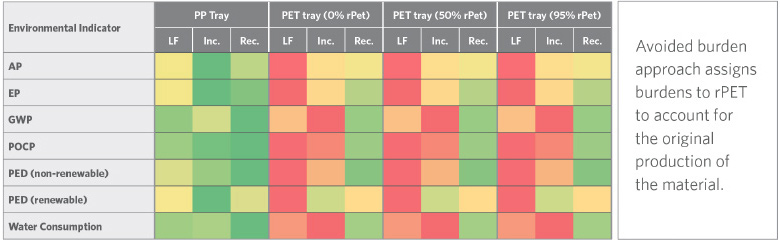

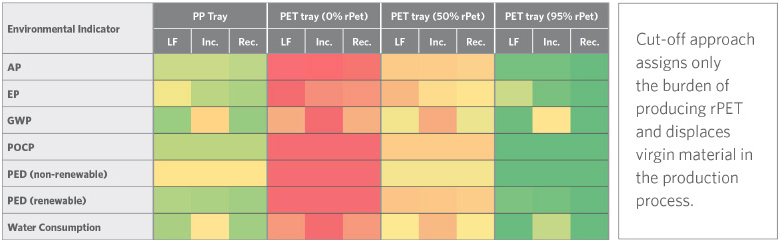

When using the avoided burden methodology, this heat map shows no difference in the PET categories as the amount of recycled PET (rPET) used to produce the tray is increased, seeming to indicate that increasing the level of recycled content does not provide any beneficial impact for PET trays in terms of a Life Cycle Assessment.

Alternatively, the cut-off approach methodology shows that as recycled content is increased, the environmental impact of the PET tray is reduced. As there are food contact grades of recycled PP available in North America, it is assumed that a similar trend would hold for inclusion of recycled PP into a PP tray. This is based on the environmental benefits of virgin resin replacement with recycled resin, as shown by the Association of Plastics Recyclers (APR).2

The impact of end of life

This LCA found that the choice of end of life scenario strongly influences the overall life cycle environmental performance. While Milliken always puts an emphasis on reuse and recycling, this LCA found that for PP trays, recycling or incineration with energy recovery are favorable end of life options depending on the environmental indicator. For PET trays, recycling is always the most preferred end of life option.

Despite this, today, PET trays are generally not recycled into packaging because contamination and color limit the market acceptance of the material. However, rPET from trays may be recycled into fiber and other applications. PP trays, on the other hand, are recycled into other PP applications ranging from storage containers to parking bumpers. rPP, however, is not commonly used in food applications due to existing regulations and a very limited supply.

In order to dramatically increase the recyclability of PP, and in a demonstration of Milliken’s commitment to sustainability, we formed a partnership with PureCycle Technologies in 2019 to accelerate the commercialization of a revolutionary technology that restores used PP to ‘virgin-like’ quality.

PureCycle’s patented recycling process, developed and licensed by Procter &Gamble, separates color, odor and other contaminants from plastic waste feedstock to transform it into virgin-like resin. Milliken’s additives will play a critical role by ensuring that the performance properties of this virgin-like resin are tailored to the application, providing a transformative opportunity to help solve the plastics end-of-life challenge.

The impact of the functional unit

The functional unit for analysis used in this LCA was equivalent mass (trays with an identical mass of 9.1g), yet it is important to note that reality may be very different. PP has a lower density than PET, therefore significantly less material would normally be required to achieve the same volume and functionality when compared to PET. For example, 1kg of PET will make 109 containers while 1kg of NX UltraClear PP will make 161 containers with these weighing 31% less at 6.2g each. Under the recycled content approach, this would notably affect the results in favor of PP, with lower impacts at levels of rPET significantly above 50%.

“This insight into the relative environmental performance of these two polymers in the given application can help to inform discussions with customers who request information on the comparative environmental performance of clarified PP and PET products,” said Paul Kearns, Sustainable Development Manager for Milliken’s Chemical Business. “We are pleased that Millad NX 8000 for PP delivers the clarity alternative to PET.”

Using life-cycle assessments to work towards a circular economy

Life-cycle assessments, like the one Milliken commissioned to compare PET and PP, have become a crucial technique for the plastics industry in the 21st century. They began in the early 1960’s when concerns began to arise over limits to the availability of raw materials and energy resources, and this sparked interest in finding new ways to account for energy, and materials, use.

At Milliken, we support Life Cycle Thinking and believe that Life Cycle Assessments, such as this one, should be considered when making choices regarding packaging materials. These standardized processes allow us to calculate and communicate the environmental impacts for a product’s life and not just its end of life.

As we all work towards a circular economy for plastics, Life Cycle Assessments are tools that producers and consumers should consider using in order to make the best possible choices for the future of our planet.

For more information on the study or for a copy of the full report “An LCA Comparison of PP and PET trays” please contact us.

The study did not assess actual recycling rates in a country or region but compared PP and PET trays based on scenarios modelling the extreme situations (100% landfill, 100% energy recovery, 100% recycling).

NX UltraClear concentrates enable polypropylene (PP) converters to achieve the highest level of transparency in their products, while also offering opportunities for faster, more cost-effective production. NX UltraClear concentrates feature Millad NX 8000 technology and are used in many thermoforming, injection molding and blow molding applications, including cups, trays, clamshells, containers, pots, foldable packaging, lids and bottles.

For more information, including the cut-off approach sensitivity analysis, please contact us.

References

1 https://ethz.ch/content/dam/ethz/special-interest/baug/ifu/eco-systems-design-dam/documents/lectures/2015/master/advanced-environmental-asses/readings/ifu-esd-msc-AESEA-Frischknecht_IntJLCA_2010_final.pdf

2 Association of Plastics Recyclers: LIFE CYCLE IMPACTS FOR POSTCONSUMER RECYCLED RESINS: PET, HDPE, AND PP December 2018; https://plasticsrecycling.org/images/apr/2018-APR-Recycled-Resin-Report.pdf