How packagers are tackling the global plastic waste problem

August 14, 2019 by Natacha KarambiziDealing with the public backlash over plastic waste

When the Belgian-born American chemist, Leo Baekeland, invented Bakelite, the first fully synthetic plastic, some 112 years ago, he would have scarcely believed the subsequent revolutionary impact his invention would have on future generations.

In many ways, plastics have revolutionized our lives. Plastics are durable, cheap-to-produce, pliable, slow to degrade and extremely versatile. From plastic bags to containers, household goods to toys, medical devices to food packaging, computers to automobiles, our everyday life is enhanced by plastic. However, through careless mis-management, plastics have become a problem for the planet’s ecosystem.

Playing an active role in reducing plastic waste

Mounting pressure from the media, the public and investors has prompted brand owners and plastic packaging manufacturers to implement aggressive goals for reducing plastic waste worldwide1. As an example, plastic packaging companies are increasingly embracing redesign and innovation to manufacture alternatives that move beyond light weighting and focus on the packaging’s next life.

When it comes to innovation in packaging and plastics, it is important for the plastics packaging industry to have a forward-looking outlook and be steadfastly committed to circular solutions for single-use packaging products. By incorporating circularity and renewability into design, single-use packaging can become reusable, recyclable and sustainable.

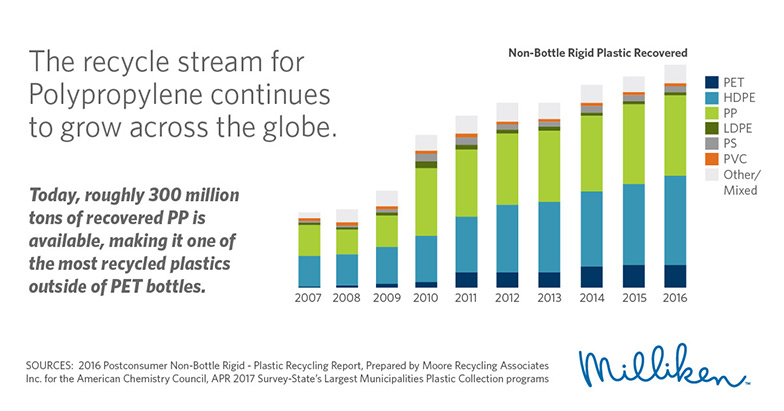

Recycling plastic packaging to reuse the materials for value-added applications is the key objective for the plastics packaging industry. Additives will play an important role in a circular future for plastics. Additives are used to upgrade the quality of recycled materials so that they can be reused in value-added applications.

Sustainable approaches should also include embracing bioplastics. Bio-based plastics break the ties to “old carbon” petroleum-based plastics. Biodegradable and compostable plastics offer new waste management options. Bioplastics, whether biodegradable, bio-based or both, offer interesting new ways to reduce our landfill waste and our carbon footprint.

Working together as an industry to reduce plastic waste

Several large global corporations are creating roadmaps to a more sustainable end product which benefits the consumer and the environment. For example, the global consumer goods company, Unilever, and the global food and drink company, Nestlé, have both pledged assurances that all of their plastic packaging will be fully recyclable or reusable by 2025. Companies such as Coca-Cola, IKEA, McDonalds and Volvo are just a small sample of fellow organizations that have pledged to make a systematic change in how they sustainably produce their goods moving forward2.

Over 400 organizations worldwide have signed on to the New Plastics Economy Global Commitment and endorse the Ellen MacArthur Foundation’s vision of a circular economy for plastics whereby plastics never become waste. Signatories have made public commitments with quantifiable goals to eliminate problematic plastic packaging, promote reuse and recyclability of plastic packaging and decouple plastics from the consumption of finite resources. As an example of the efforts of the plastics industry, Borealis and Indorama, both resin producers, are committing to shift their existing business model which is based on extracted and virgin materials to one based on circulation of materials3.

Committed to developing new sustainable technologies in plastics

Reduce, reuse, recycle. Together we must rethink how we use plastics and explore innovative ideas for the reuse and recycling of plastic packaging. In the end, it is everyone’s goal to create an environmentally sustainable product for the consumer.

At the grand opening of the Milliken Packaging Innovation Center in Shanghai in April 2018, Dr. Ed Zhao, Senior Vice President and Managing Director of Asia-Pacific at Milliken, echoed these sentiments when he said, “We are committed to working with our customers to develop new technologies that make polyolefins the material of choice in our modern world. Together, we can make people’s lives easier, more convenient and better for the environment overall.”

From the manufacturer to the packager to the consumer, we must continue to work together to reduce plastic waste.

Related links

Plastic packaging getting smarter and greener

References

1 “The New Plastics Economy: Rethinking the future of plastics & catalysing action,” The Ellen MacArthur Foundation. https://www.ellenmacarthurfoundation.org/publications/the-new-plastics-economy-rethinking-the-future-of-plastics-catalysing-action (accessed February 17, 2019).

2 “What are businesses doing to turn off the plastic tap?,” UN Environment. https://www.unenvironment.org/news-and-stories/story/what-are-businesses-doing-turn-plastic-tap (accessed February 20, 2019).

3 “NEW PLASTICS ECONOMY GLOBAL COMMITMENT: JUNE 2019 REPORT,” The Ellen MacArthur Foundation. https://www.ellenmacarthurfoundation.org/assets/downloads/GC-Report-June19.