Achieving premium performance with standard PP resin grades

August 17, 2021 by Emily BlairA year into the COVID-19 pandemic, the crisis has disrupted the world economy and touched businesses in almost every country. One of the larger economic impacts has been the roller coaster effect on material prices for plastics processors.

In March 2020, as populations all over the world went into lockdowns, demand initially fell and as a result, prices plunged. However, as the first wave, and lockdowns in Europe and parts of the United States, came to an end, increasing demand for housewares and durable goods, combined with supply chain disruptions due to weather events in the US, drove prices well above norms for some resins.

In addition, polypropylene (PP), specifically, has seen a boost in global demand as it is widely used for the production of essential COVID-19 PPE (personal protective equipment) such as masks and hospital gowns. This has led to a shift in availability for traditional copolymer PP grades and has created serious supply shortages.

The shortages and high prices of PP have forced many processors to use lower, therefore cheaper, grades of PP to get by, but that comes at the cost of diminished physical properties and poor melt flow performance which increases processing costs and can cause quality problems.

A proven solution

Fortunately, there is a product that removes this compromise. Described as a novel reactive extrusion modifier, Milliken’s DeltaMax™ family of masterbatch performance modifiers is a radical advancement in additive technology for PP impact copolymers (ICPs) as well as recycled PP. DeltaMax improves both the physical properties and the processability of copolymer polypropylene so that it can serve more demanding applications whilst still reducing processing costs.

The technology enables injection molders to enhance the impact and melt flow of their ICP or rPP resins by adding a masterbatch at machine-side. The net effect is the ability to produce parts with higher impact resistance and thinner profiles, run machines with faster cycle times and lower temperatures, reduce the use of costly impact modifiers, and reduce inventory of multiple ICP resins.

Changing the economics of processing polypropylene

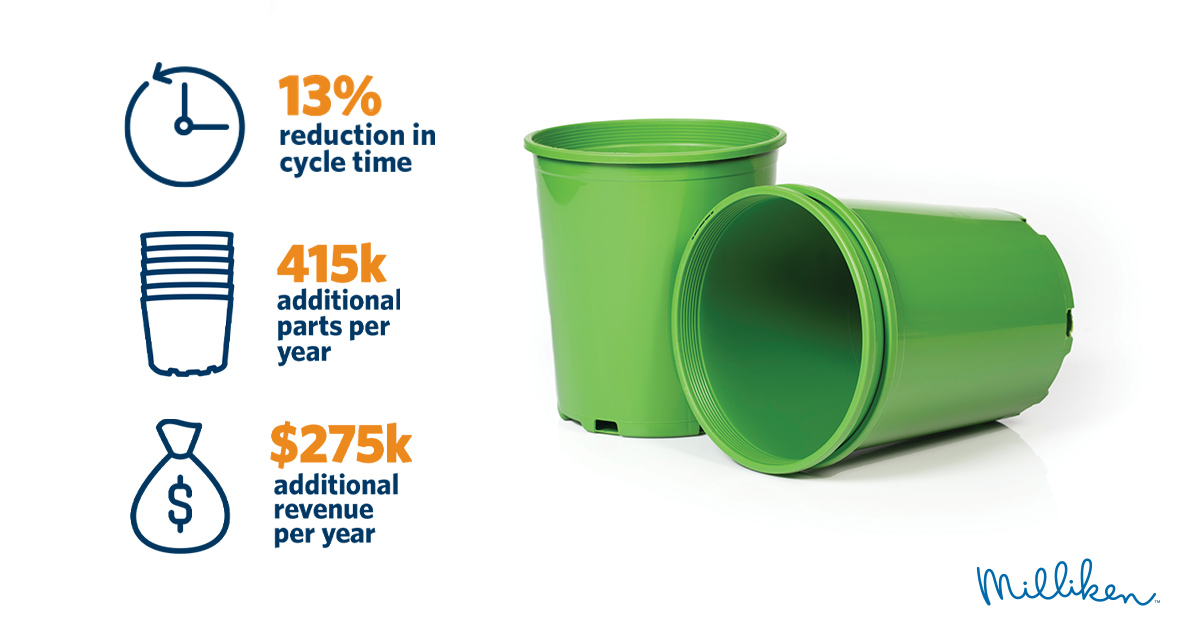

One recent example of where DeltaMax has enabled dramatic improvements to injection molded products is the case of a horticultural container manufacturer that was attempting to increase throughput and reduce processing costs of its 2.65 gallon flower pots.

The challenge: parts would become defective because higher melt flow resins produce brittle parts that break easily. Conversely, lower melt flow resins could lead to product defects, such as short shots and inconsistent parts. Using DeltaMax m100 Melt Flow Modifier at 0.5% loading allowed the company to reduce processing temperatures by 14%, resulting in shorter cooling times and a cycle time reduction of 13%. Throughput improvements of 415,000 pots resulted in $275,000 of additional revenue with significant margin improvement.

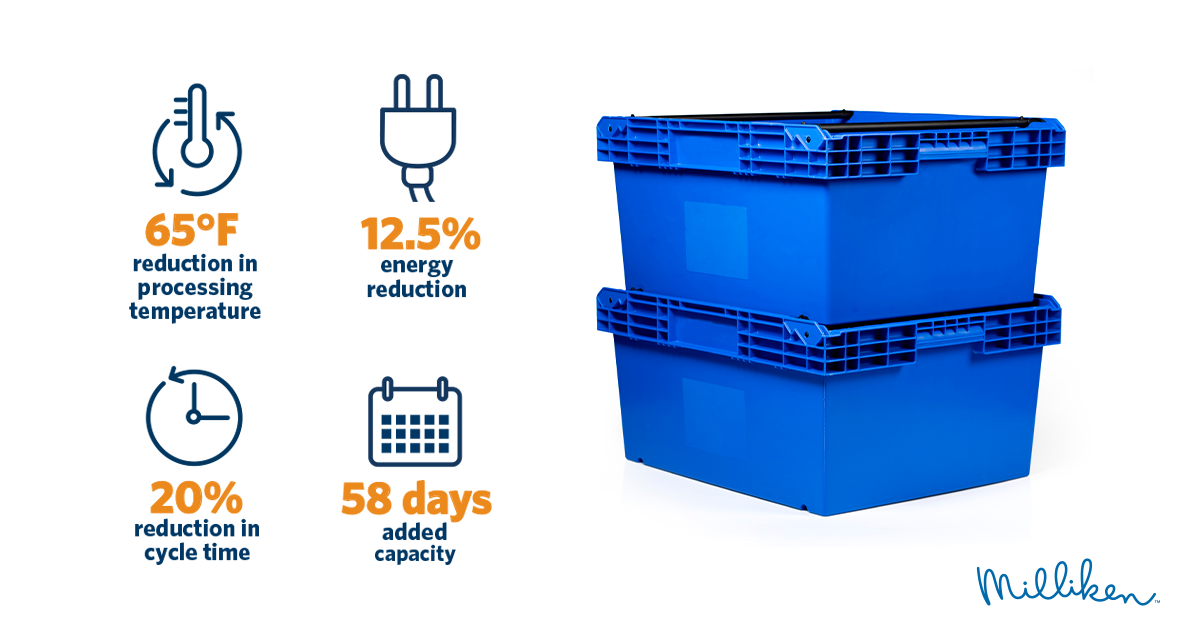

In another case study, a manufacturer of material handling containers was attempting to improve the output of its injection molding machines. While the company was investing in new presses they still were fighting with capacity constraints. They considered the use of resins with better melt flow characteristics for faster processing, but the physical performance was not acceptable and the cold temperature impact properties fell below an acceptable range.

Using DeltaMax a200 at 1.0% LDR enabled a cycle time reduction of 20%, resulting in an estimated annual throughput increase of 110,000 containers. Productivity improvements and energy savings yielded an additional 58 days of production which resulted in $2 million in additional revenue at 20% margin.

Performance and sustainability

In addition to their superior performance, DeltaMax modifiers allow for the use of recycled PP at equal or better performance levels compared to virgin resins, creating an opportunity to improve the circular economy and promoting more sustainable manufacturing practices.

From a climate perspective, PP generally has a low carbon footprint, making the use of greater amounts of rPP important to many processors’ sustainability initiatives. However, using recycled PP has, until now, typically come at the price of poor processability and increased part defects, including flashing, sink marks and most common, short shots.

Some processors compensate by running at higher temperatures to improve melt flow and fill out their molds. That too has a cost by leading to degradation of the plastic with substantial loss in impact properties. It also increases energy use and creates more wear and tear on the equipment. DeltaMax mitigates these compromises by improving processability at lower temperatures, resulting in higher quality products in a more cost effective and sustainable environment.

As we still grapple with the impacts of COVID-19, and look further into the future at the bigger picture sustainability challenges we face, it’s clear that DeltaMax performance modifiers have both an immediate and longer-term role to play in producing high quality and more sustainable PP products.